Developments in screening media from Tema Isenmann.

19 March 2013

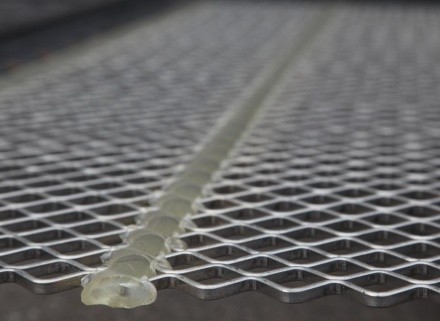

Now available, ISEREC flat-wire harp sieves are manufactured from upright, adjacently positioned flat wires that are held together by steel or polyurethane cross bindings to form a sturdy square mesh. The pitch of the cross bindings can be individually adjusted to suit the screening machine’s support structure and the material to be screened.

When installed in a vibrating screening machine the upright wires of the ISEREC flat-wire harp oscillate as a result of the large span of the cross bindings. This achieves very effective screening, with minimal blinding and accurate separation.

The robust construction offers a service life several times longer than traditional self-cleaning harps produced with round wire.

ISEREC flat-wire harp is predominantly used in highly abrasive and heavily loaded applications where damp/moist materials that are difficult to screen, tend to blind and adhere with conventional wire meshes.

Available in Spring Steel (DIN EN 10270-1) or Stainless Steel (1.4301) with a maximum wire screen width of 2500mm in various apertures ranging from 4.0mm to 39.0mm.

Tema Isenmann are based in Woodford Halse, Northamptonshire and supply a full range of screen systems including woven wire, harp sieves, rubber and polyurethane in tensioned and modular formats.